Article

Shortcuts to article's themes:

> Basics

> Physics

> Aesthetics

> Next-generation Fresnel

> Conclusions

Finding the perfect spot – The art and science of narrowing beam angles

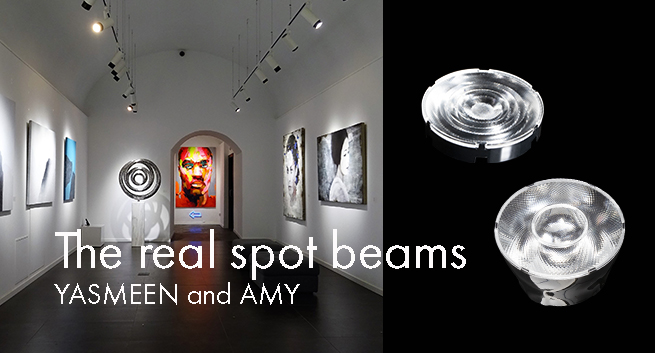

Exploring the role of optics, physics, and aesthetics in achieving tighter spot beams for retail and architectural applications

Over the years, our team has received numerous requests from customers for spot beams with tighter angles. While achieving even a 1-degree beam angle is relatively straightforward without size limitations, creating a more focused beam with a larger light source presents a significant challenge. We also understand that using a bigger optic for the desired narrow beam is not always feasible, as products are optimised for their standard sizes and wider beam range. Additionally, miniaturisation is a strong trend in the industry. While LEDiL is passionate about pushing boundaries, it is important to understand the physical constraints to arrive at the best possible solution.

Basics

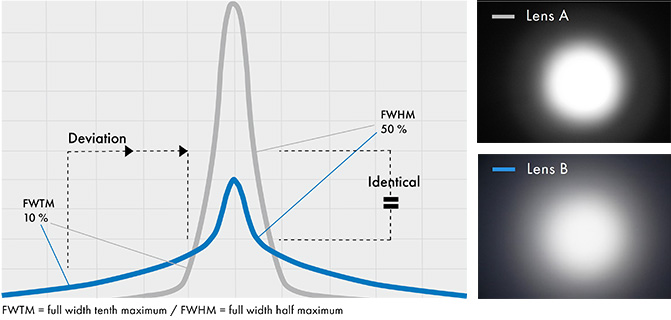

In illumination engineering, understanding the Full Width Half Maximum (FWHM) and Full Width Tenth Maximum (FWTM) angles is crucial to evaluate optical component performance. FWHM is the width of light distribution at half the peak level, while FWTM is the width at one-tenth the peak level. FWHM alone doesn’t indicate the total light distribution, so FWTM is needed for a better understanding of performance.

The FWHM value alone is insufficient to evaluate the performance of an optical component.

For example, the two lenses shown in the illustration above have the same FWHM angle. However, lens A (grey line) exhibits much higher optical intensity (cd/lm) and a more concentrated beam, as indicated by a narrower FWTM value. In contrast, lens B (blue line) has relatively lower intensity, with a larger portion of light falling outside the central beam area, resulting in a wider FWTM value. When comparing different optical components, it’s important to consider both FWHM and FWTM values.

Physics

Most lighting tasks can be accomplished with narrow beams ranging from 15–24 degrees for which typical lighting fixtures and LED sizes are optimised. However, for more specialised tasks, a narrower beam of 6–10 degrees may be necessary. For example, in a museum with a high ceiling, a 15-degree beam may spill over the intended area, while an 8-degree beam will do the task with sacrifice on efficiency. In the past halogen lights were used to achieve narrow beams, but there are better alternatives available nowadays.

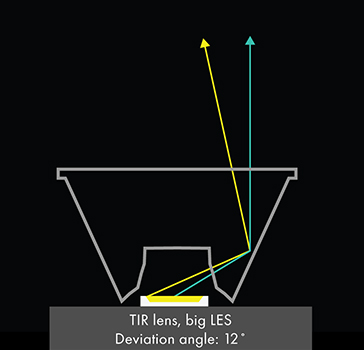

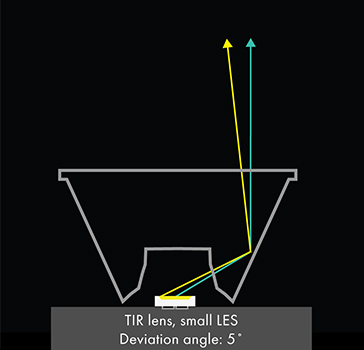

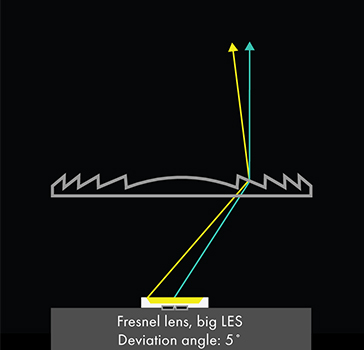

Optical components, such as lenses and reflectors, work by reflecting or refracting light in a fixed way. While collimators work best with a theoretical point source, LEDs like COBs do not emit light from a single point. Instead, the light comes from different angles and deviates from the desired direction. The degree of deviation angle is affected by the accuracy of the optic as well as the size of the COB. For achieving ultra-narrow deviation angles Fresnel optics offer an alternative to traditional TIR lenses. Positioned farther from the light source, Fresnel lenses enhance collimation accuracy and reduce light spill. As shown in third picture below, a Fresnel lens with a large LES can achieve the same deviation angle as a TIR lens with a small LES.

Deviation angles of TIR and Fresnel optics with small and large LES sizes.

If the physical limits are reached, adjustments can be made to the size of the optic or LED. Making the optic larger or the LED smaller can reduce the deviation angle and create a closer-to-point-source effect. If increasing the optic size is not possible, a smaller LED with higher lumen density can be used. Narrow beams have a higher candela peak, so extra-narrow beams can achieve enough intensity with fewer lumens than wider beams.

Sometimes, using multiple smaller sources with an array of lenses can result in better accuracy, but it may also require compromises compared to a typical solution.

Track light example with multiple LEILA-Y optics for museum lighting.

Aesthetics

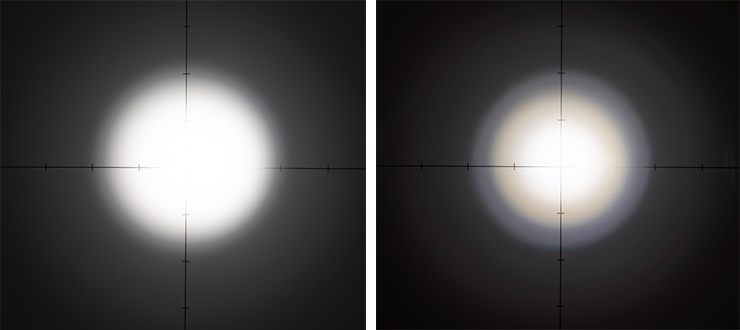

The spots are not all the same, as explained in our article. A theoretical collimator produces an image of the LED with colour uniformity issues, which the lens needs to compensate for. The beam angle also plays a significant role, as the beam needs a sharp cutoff without much stray light after the main beam. Achieving a tight beam is not enough in many applications; it must also be aesthetically pleasing for retail and architectural lighting. Colour mixing features in the lens are crucial for high-quality lighting. A lens with colour mixing features produces beautiful, uniform, state-of-the-art lighting, while a lens without such features is inadequate for high-quality spot lighting despite having the narrowest and most intensive beam.

Example of a spot lens with and without colour mixing features.

Next-generation Fresnel

Fresnel lenses have long been valued for their precise collimation, but achieving both high optical performance and aesthetics has been a challenge. Traditional designs often suffered from color aberrations and visual inconsistencies, limiting their use in applications where both precision and appearance matter.

LEDiL’s new patent-pending Fresnel solution overcomes these limitations, maintaining a narrow beam while significantly enhancing aesthetics. Unlike TIR optics, Fresnel lenses are positioned farther from the light source, allowing for superior collimation and reduced light spill. While this design may introduce minor efficiency losses, our approach ensures that just as much light reaches the target as with conventional TIR optics—only with greater accuracy.

LEDiL’s new patent-pending Fresnel solution enables an ultra-narrow yet beautifully uniform beam.

Designed for ultra-narrow (<5°) beams, this solution prioritises peak candela (intensity) over total lumens, delivering sharp, high-intensity beams suited for demanding applications. These advancements enable:

Long-range illumination – focused beams reaching greater distances.

Dramatic lighting effects – strong contrasts and well-defined edges.

Precision for small objects – minimised stray light for targeted illumination.

With these improvements, Fresnel optics are now a powerful tool for applications that demand both precise beam control and high-quality light distribution.

Conclusions

The size of the light source (LES size) and the choice of optics are key factors in determining a spotlight’s beam angle. A smaller light source creates a narrower beam, often enhancing contrast and producing a stronger candela peak for a more refined lighting effect. Conversely, larger optics can also help focus the beam. However, a larger light source, while generating more light, may cause spill outside the target area, reducing overall intensity.

The beam can be further narrowed by using multiple single lenses in a single track light, where the light source is relatively small compared to the lens size.

For ultra-narrow beams, Fresnel lenses provide precise collimation and minimise stray light. Their ability to maintain beam focus, enhance contrast, and improve aesthetics makes them ideal for applications requiring long-range or highly targeted lighting.

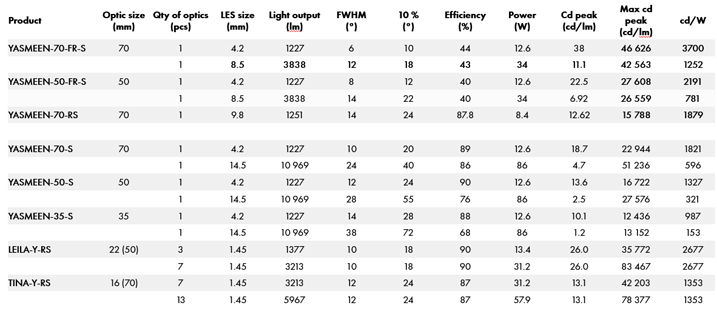

Comparing the characteristics of spot optics with varying sizes and LES configurations.

Our team is constantly striving to innovate and push the limits of spot lighting solutions. While we sometimes encounter requests that may not be feasible due to physical constraints, we are always happy to collaborate with our clients to find alternative concepts or compromises to meet their needs.

Shortcuts to article's themes:

> Basics

> Physics

> Aesthetics

> Next-generation Fresnel

> Conclusions